BRAKE CALIPER CAPSCREWS. S/S REPLACEMENT?

Moderators: slparry, Gromit, Paul

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

BRAKE CALIPER CAPSCREWS. S/S REPLACEMENT?

Is it possible (safe?  ) to replace the 4 capscrews that hold the two halves of the (3)calipers together (mine are really manky

) to replace the 4 capscrews that hold the two halves of the (3)calipers together (mine are really manky  ) with stainless ones without draining and dismantling the unit? One at a time maybe? Has anyone done this? What type/size do I need?

) with stainless ones without draining and dismantling the unit? One at a time maybe? Has anyone done this? What type/size do I need?

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Just hot-bolt them - no problem.

I think they are M8, but can't remember the length.

Take one out, measure it and return it - then go out and buy the stainless ones.

Get decent stainless, though

make sure you smear oil on the stainless bolts (and if hot-bolting - I would use molykote, as you are not opening the caliper mating-faces)

Al

I think they are M8, but can't remember the length.

Take one out, measure it and return it - then go out and buy the stainless ones.

Get decent stainless, though

make sure you smear oil on the stainless bolts (and if hot-bolting - I would use molykote, as you are not opening the caliper mating-faces)

Al

If I am ever on life support - Unplug me......

Then plug me back in..........

See if that works .....

Then plug me back in..........

See if that works .....

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

Well I've removed a bolt and sized it (M8x40) but nothing's ever straight-forward with BMW is it.  The head's a different shape from a standard cap screw and they're 'waisted' down to 7m/m for the part of their length that's exposed when they're fitted.

The head's a different shape from a standard cap screw and they're 'waisted' down to 7m/m for the part of their length that's exposed when they're fitted.  BTW, What's 'Hot-Bolt' mean Al?

BTW, What's 'Hot-Bolt' mean Al?

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Sorry - my post was a bit superfluous - I started it, read a couple of e-mails, and by the time I had completed the post - it had already been suggested.

Hot-bolting is just changing out bolts one at a time. More often than not - on live low pressure systems.

Al

Hot-bolting is just changing out bolts one at a time. More often than not - on live low pressure systems.

Al

If I am ever on life support - Unplug me......

Then plug me back in..........

See if that works .....

Then plug me back in..........

See if that works .....

I straight swapped one at a time, M8 X 40; and ground the ends off if they protruded beyond the caliper body. Great fun getting the OE bolts out I recall. It is also worth remembering there at least two grades of stainless bolts (A2; A4 I think) + the awful inferior Chinese ones. I always fit marine quality. The price is a useful gauge.

Last edited by oyster on Sun Jul 15, 2012 5:17 pm, edited 1 time in total.

Oyster. 1999 R1100S. Almost original.

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

Blackal wrote:Hot-bolting is just changing out bolts one at a time. More often than not - on live low pressure systems.

Al

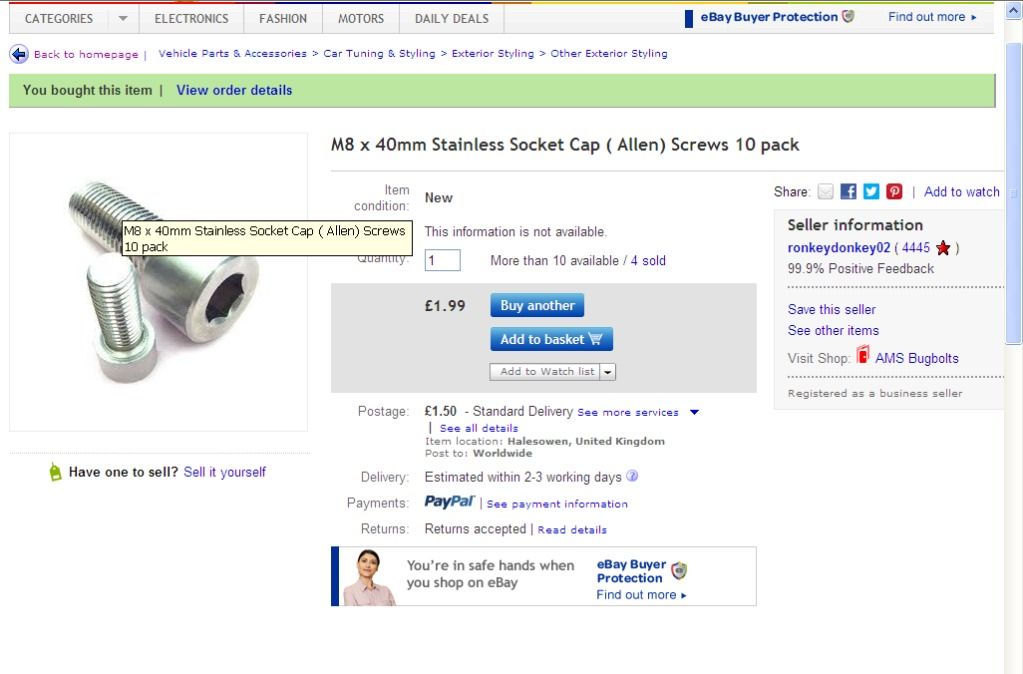

Just ordered these (x2)

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

-

northern donkey

- Posts: 27

- Joined: Thu Jun 21, 2012 5:40 pm

- Location: DEVON

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

I can see there may be a reason BM waisted (Disc clearance? Do they run that close?  ) the OE bolts. But why go to the trouble of fitting a cap screw with a head shape that at least I've never seen before?

) the OE bolts. But why go to the trouble of fitting a cap screw with a head shape that at least I've never seen before?

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

I don't remember there being locating dowels between the two caliper halves.....

That being the case - the increased diameter at the cap-head end is for location of the two halves- I would reckon.

On more critical bolts (bottom end bolts) the main structure of the bolt is reduced from the thread diameter - to prevent stretch of the bolt in the thread-section. You'll often see short sections of the bolt increased out to the thread diameter - to locate the bolt in the hole.

Al

That being the case - the increased diameter at the cap-head end is for location of the two halves- I would reckon.

On more critical bolts (bottom end bolts) the main structure of the bolt is reduced from the thread diameter - to prevent stretch of the bolt in the thread-section. You'll often see short sections of the bolt increased out to the thread diameter - to locate the bolt in the hole.

Al

If I am ever on life support - Unplug me......

Then plug me back in..........

See if that works .....

Then plug me back in..........

See if that works .....