snapped exhaust stud (R1200S)

Moderators: Gromit, Paul, slparry

Not much to play with there, I would stay away from the mole grips and go with Merecat's method. Good quality stud extractor is a must because trying to drill out a broken stud extractor is no fun at all. Ask me how I know.

If it were mine, I would be getting it on a trailer to Dave East's workshop near Leicester. Old school guy, this kind of stuff is his bread and butter.

If it were mine, I would be getting it on a trailer to Dave East's workshop near Leicester. Old school guy, this kind of stuff is his bread and butter.

********Jim********

---------------------------

2006 'Colgate' R1200s

---------------------------

2006 'Colgate' R1200s

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

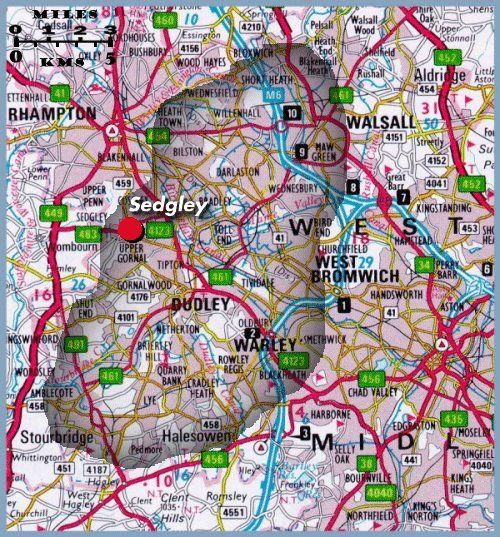

exoticices wrote:I'm originally a Blackheath boy, then we moved to Rowley Regis (it's royal you know). We only recently moved over this way. We don't go on the moors at night.

'cordin' my 'Map of the Black Country' you definitly qualify then. And don't worry. If the worst comes to the worst you can always drill and tap for the next size up and fit a stepped stud. Or fit a 'Helicoil' thread insert.

Last edited by el-nicko on Sun Dec 23, 2012 7:03 pm, edited 1 time in total.

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

- Boxadog 2000

- Member

- Posts: 1908

- Joined: Wed Feb 18, 2004 8:29 pm

- Location: Looking over hedges

If you insist on trying to use a stud extractor do not use a carbon steel one IT WILL BREAK.

You absolutely have to drill the hole dead center then get a good quality Torx bit and hammer it in followed by putting a socket on the remainder and unscrewing .

Sorry to say that you have a less than 10% chance of success.

Please prove me wrong

You absolutely have to drill the hole dead center then get a good quality Torx bit and hammer it in followed by putting a socket on the remainder and unscrewing .

Sorry to say that you have a less than 10% chance of success.

Please prove me wrong

- Dai wiskers

- Member

- Posts: 1262

- Joined: Mon Jul 09, 2012 7:21 pm

- Location: Caerphilly

I find a centre punch attacked with a grinder so it has a fine square or triangular end and grind two flats on other end best for this sort of job, drill the stud carefully hammer the centre punch into the stud undo with spanner on the end of the punch usually works

You may find these usefull for the future and worth trying first though http://www.amazon.co.uk/Irwin-T394100-P ... _gw_s_cp_7

The socket type for goosed nuts work well so i would think these will too

I hate having to drill a stud or snapped bolt out and always try to avoid it

You may find these usefull for the future and worth trying first though http://www.amazon.co.uk/Irwin-T394100-P ... _gw_s_cp_7

The socket type for goosed nuts work well so i would think these will too

I hate having to drill a stud or snapped bolt out and always try to avoid it

My bike shines when it rains!!!!!!!!!!!!!!!!!

Dyslexic Dai

Steptoe

http://www.gsshop.biz/

Dan Cata

http://boxer-upgrades.webs.com/

Lennie

http://www.boxer-performance.com/index.html

Dyslexic Dai

Steptoe

http://www.gsshop.biz/

Dan Cata

http://boxer-upgrades.webs.com/

Lennie

http://www.boxer-performance.com/index.html

I have found that Eazyouts (they got that wrong) only work if the bolt has been broken from over tightening, not from being seized and broken trying to remove.

My suggestion is as someone else said, carefully drill out the old bolt and retap the hole. If that fails http://www.ebay.com.au/itm/25pc-THREAD- ... 797wt_1160

You might as well replace all of the exhaust studs while your at it. If you Helicoil all of the holes you could fit S/Steel Allen head bolts.

Dave

My suggestion is as someone else said, carefully drill out the old bolt and retap the hole. If that fails http://www.ebay.com.au/itm/25pc-THREAD- ... 797wt_1160

You might as well replace all of the exhaust studs while your at it. If you Helicoil all of the holes you could fit S/Steel Allen head bolts.

Dave

99 R11s Pov. Spec.

92 RGV250 Race Spec. Australian Land Speed Record Holder MPS/G 250 131 MPH http://www.dlra.org.au/index.htm

85 RZ250 Yamaha Std.

85 RZ250 Yamaha Spares.

84 RZ250 Yamaha Banshee 350 top end.

84 RZ250 Yamaha Rebuilding for sale.

92 RGV250 Race Spec. Australian Land Speed Record Holder MPS/G 250 131 MPH http://www.dlra.org.au/index.htm

85 RZ250 Yamaha Std.

85 RZ250 Yamaha Spares.

84 RZ250 Yamaha Banshee 350 top end.

84 RZ250 Yamaha Rebuilding for sale.

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

South_Oz wrote:I have found that Eazyouts (they got that wrong) only work if the bolt has been broken from over tightening, not from being seized and broken trying to remove.

My suggestion is as someone else said, carefully drill out the old bolt and retap the hole. If that fails http://www.ebay.com.au/itm/25pc-THREAD- ... 797wt_1160

You might as well replace all of the exhaust studs while your at it. If you Helicoil all of the holes you could fit S/Steel Allen head bolts.

Dave

All good points Dave. Can I add?... When I worked in a tool and die repair shop, removing broken studs was a fairly regular thing. Always made easier tho 'cos it was usualy possible to mount the part on a mill or EDM and therefore drill/erode with some acuracy. A luxury (short of removing the cylinder head) not available in this case. One method we used to employ, in the case of a broken off stud that was rusted/seized in, was to drill slightly off centre

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

- Dai wiskers

- Member

- Posts: 1262

- Joined: Mon Jul 09, 2012 7:21 pm

- Location: Caerphilly

Another option is to weld a nut onto whats left of the stud it looks like there's just enough thread showing to do it and the heat should loosen off the stud a nut without any coating on will work best if you must use a new nut run a drill through it first to remove any thread and coating zinc or chrome

remember to remove earth from the batt and you should be good to go

remember to remove earth from the batt and you should be good to go

My bike shines when it rains!!!!!!!!!!!!!!!!!

Dyslexic Dai

Steptoe

http://www.gsshop.biz/

Dan Cata

http://boxer-upgrades.webs.com/

Lennie

http://www.boxer-performance.com/index.html

Dyslexic Dai

Steptoe

http://www.gsshop.biz/

Dan Cata

http://boxer-upgrades.webs.com/

Lennie

http://www.boxer-performance.com/index.html

It will come out

trick is to be patient, drill a small guide hole ( slowly) in exact centre, this is a guide for a larger bit. You need to increase the size of the hole gradually to enable you to use the largest extracter you can possibly use on that size stud without the stud outer collapsing.

wind the extractor in slowly but more importantly evenly, as deep as possible, once it bites use a long reach bar of some sort to wind in, its a `torque` thing.

Stud extractors work really well, but only if the right size is used for the job and there wound in true. If you need to buy one don`t skimp on a cheap set from machine mart or such like, it makes the job longer when you have to extract the extractor!

cheers

Steve

trick is to be patient, drill a small guide hole ( slowly) in exact centre, this is a guide for a larger bit. You need to increase the size of the hole gradually to enable you to use the largest extracter you can possibly use on that size stud without the stud outer collapsing.

wind the extractor in slowly but more importantly evenly, as deep as possible, once it bites use a long reach bar of some sort to wind in, its a `torque` thing.

Stud extractors work really well, but only if the right size is used for the job and there wound in true. If you need to buy one don`t skimp on a cheap set from machine mart or such like, it makes the job longer when you have to extract the extractor!

cheers

Steve

- el-nicko

- Member

- Posts: 1562

- Joined: Tue Mar 13, 2012 3:04 pm

- Location: Nick from HEREFORDSHIRE, The Oceanian province of Airstrip One.

Pity the weather's not better. We cud all turn up at this bloke's (with the unpronounceable name) place and have a :occasion7: 'PULL MY STUD':occasion7: (HOW DO U PULL YORS?) PARTY!  .

. ![mutley laugh [smilie=mutley laugh.gif]](./images/smilies/mutley laugh.gif) Happy Xmas everybody.

Happy Xmas everybody.

.

. ![mutley laugh [smilie=mutley laugh.gif]](./images/smilies/mutley laugh.gif) Happy Xmas everybody.

Happy Xmas everybody.

Last edited by el-nicko on Sun Dec 30, 2012 10:28 pm, edited 2 times in total.

.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

Mr. Spock is my role model so be advised; I possess no (discernible) sense of humour.

It's all VFR (DCT) round here now. STILL missing my 1100s tho.

- exoticices

- Posts: 260

- Joined: Sat Jul 21, 2007 5:19 pm

- Location: West Midlands

Well, It feels like I spent Christmas eating mince pies and squirting releasing fluids onto pesky header studs.

Eventually I did what I should have done in the first place and took it to (a) someone who knows what they're doing, and (b) someone who has the correct tools - a local bike shop - www.projex-uk.co.uk - proper 'old school' guy and very helpful.

After sucking teeth and muttering something about boxers, it took him less than 2 minutes to get the stud out using some sort of stud extractor that looked like it would have done well during the Spanish Inquisition. "You're lucky", he proclaimed.

Cost? "A drink." Well pleased. I think he took pity on me choosing the wettest day of December to take the bike in.

Also, thanks to Motorworks who don't carry the studs in stock but said they'd order them and get them despatched to me during the week before Christmas and were true to their word. Good price too. Excellent service.

Thanks to everyone for their advice.

Eventually I did what I should have done in the first place and took it to (a) someone who knows what they're doing, and (b) someone who has the correct tools - a local bike shop - www.projex-uk.co.uk - proper 'old school' guy and very helpful.

After sucking teeth and muttering something about boxers, it took him less than 2 minutes to get the stud out using some sort of stud extractor that looked like it would have done well during the Spanish Inquisition. "You're lucky", he proclaimed.

Cost? "A drink." Well pleased. I think he took pity on me choosing the wettest day of December to take the bike in.

Also, thanks to Motorworks who don't carry the studs in stock but said they'd order them and get them despatched to me during the week before Christmas and were true to their word. Good price too. Excellent service.

Thanks to everyone for their advice.

(John)

https://www.facebook.com/xiaomei.griffiths

http://samslunarlookin.blogspot.co.uk/

http://samsswingnskank.blogspot.co.uk/

In a fifty mile race I am the best, I ride five miles and skid the rest.

https://www.facebook.com/xiaomei.griffiths

http://samslunarlookin.blogspot.co.uk/

http://samsswingnskank.blogspot.co.uk/

In a fifty mile race I am the best, I ride five miles and skid the rest.

- Nookiebear

- Posts: 128

- Joined: Thu Nov 08, 2012 9:04 pm

- Location: Outer London

Heli coils can sometimes be a little tricky, I recommend using Time-Sert set (www.timesert.com) as they are idiot proof, if I can use them anyone can.

Who is online

Users browsing this forum: No registered users and 285 guests